As the largest furniture manufacturer in the world, Ashley Furniture didn’t sleep on an opportunity to bolster operations and upgraded their Houston distribution center with an LED lighting solution.

The Opportunity

Ashley Furniture is considered a world-class furniture manufacturer, drawing from over 65 years of design and manufacturing innovation. In keeping with their vision to be the best furniture company, they closely pay attention to their logistics operations – the network between manufacturing quality furniture and distributing it to the customer. With more than 7,000 product SKUs in over 22 product categories, their distribution facilities must streamline operations and systems to manage a significant amount of inventory.

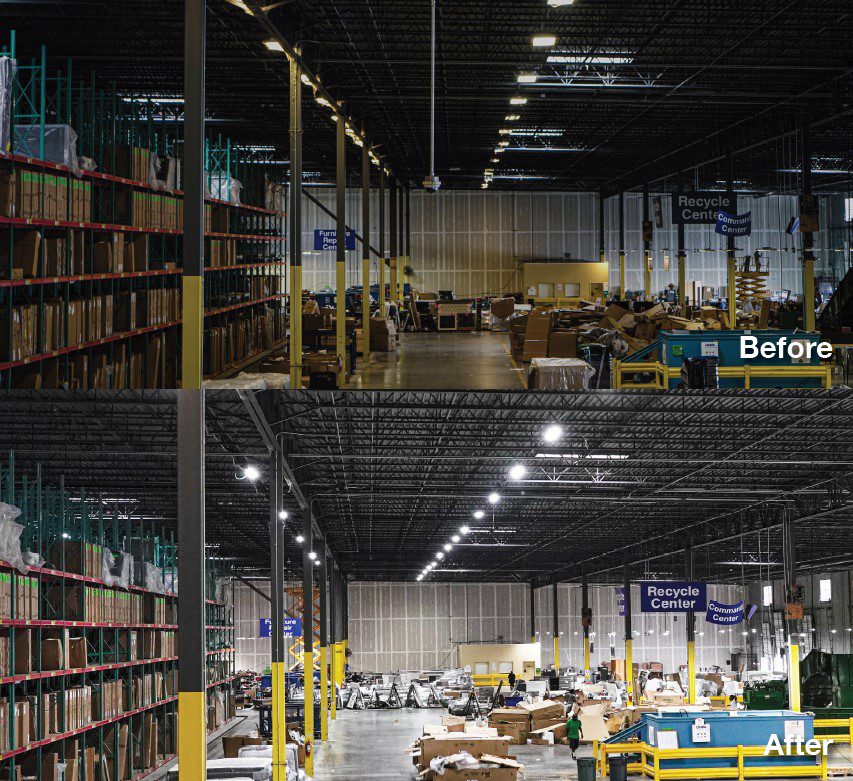

The Houston distribution center is a strategic location that makes up almost 600,000 sq. ft. of warehouse floor space under one roof. Lighting conditions at this facility had deteriorated to the point that critical spaces like aisles, unloading positions, and inspection areas had light levels of only 5-15 footcandles on the ground. It wasn’t uncommon to see the fluorescent high bays and tube fixtures out of commission or have different color temperatures (CCT) intermingled. Aside from high energy consumption and maintenance issues, employees complained about the poor lighting making it difficult to perform tasks. Efficiency and safety of employees became significantly important, and they quickly realized that better lighting could make a substantial difference for overall operations. At a facility of this size upgrading the lighting would be a logistical challenge, so finding a qualified partner to install a new LED solution without interrupting

The Solution

After vetting multiple vendors, Ashley Furniture chose to partner with the lighting experts at National LED. Working collaboratively, they developed a lighting solution that would work best for the distribution center location without interrupting operations. The team determined that US LED’s BayLine LED high bay would be the best combination of light output, energy savings, and reduced maintenance.

At a projected 200,000-hour L70 lifetime, the BayLine is the smart choice for warehouses, industrial areas, manufacturing facilities, and other large commercial spaces. It offers multiple choices of lumen packages and lens distributions so that you can get the light exactly where it’s needed, especially in-between the warehouse racking. For this facility, the team was able to perform a one-for-one replacement of all the fluorescent high bays and tube fixtures. By also installing occupancy sensors, the lighting could be controlled to only turn on when movement is detected and turn off when the area is clear after a pre-determined amount of time.

The Benefits

The enhanced quality of illumination was immediately well received and made a noticeable impact on employee safety, morale, and the efficiency of operations. Prior to the LED lighting upgrade, some employees had to utilize additional light sources to perform their tasks, especially in-between the warehouse racking. Visibility in the warehouse has significantly improved due to the uniformity and increased light levels have doubled or even tripled up to 50 footcandles on the ground. With the energy-efficient BayLine LED high bays, Ashley Furniture will see an estimated annual reduction of 374,000 kWh. Additionally, they will have the confidence of avoiding costs associated with the maintenance of legacy fluorescent fixtures on a regular basis. They ultimately can expect a 200,000-hour L70 product lifetime for each BayLine LED high bay and will enjoy the security of knowing they are backed by an industry-leading 10-Year Warranty. Even